Lorem Ipsum has been the industry's standard dummy text ever

When your needs have changed but you want to maintain the integrated factory look, we can help.

Top grade materials, components and engineering combined with instrustry leading manufacturubg capabilities allow us to produce consistent results you can trust.

Every project begins with a concept, each unique in its own way. Our approach is to listen carefully to the clients needs and then deliver a custom finished product that reflects their vision and exceeds their expectation.

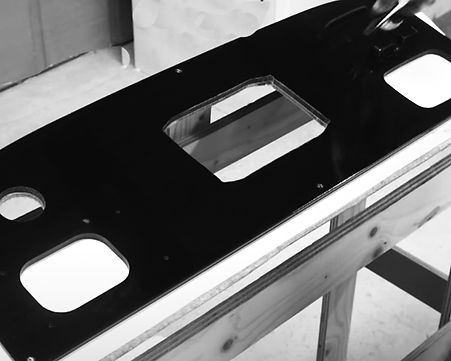

Our first step in the design process is to look at the aesthetics, determine the application, and select materials that will drive the look and feel of their finished panel. We offer a wide variety of precision machined UV resistant ABS material and stainless milled to the specs to fit your boat perfectly.

Download the custom panel design guide for more information and to get your project started!

Now that we know what we want to do, the next step of the process is to determine the required components for the build. During this selection process we give careful consideration to form and fit of each component along with the fucntionality.

It is very common for clients to have specific components they wish to integrate into their custom panel and that is easy for us to accomadate. At the same time, we are a great resource for making suggestions and providing options that help tie the project togteher.

Once the materials and components are defined, we turn our attention to functionality. We focus on layout, spacing, and user interaction based on the feedback our client has provided. We want to ensure the usability of the panel is intuitive and natural.

After this has been finalized, we use the layout to produce the proof. Once accepted, the project moves to production.

100% of our custom instrument panels are produced in house. This gives us total control of the process and ensures consistency in our products.

We utilize cutting edge CNC, laser, and water jet technology to cut, shape, route, and label material with precision to ensure your project meets spec.

For many of our projects we are able to completely assemble the finished product. This allows us to confirm the fit and trim are accurate before your project ships.

While some of our clients have staff technicians to handle their install, we realize others do not. As a result, many of our dealers offer installation services through their service departments. To find a list of those dealers, please check out our contact page.

If you can't locate a dealer near you, please just reach out to one of our crew members. We can schedule one of our factory service tech's to assist you.